TECHNOLOGY

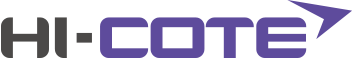

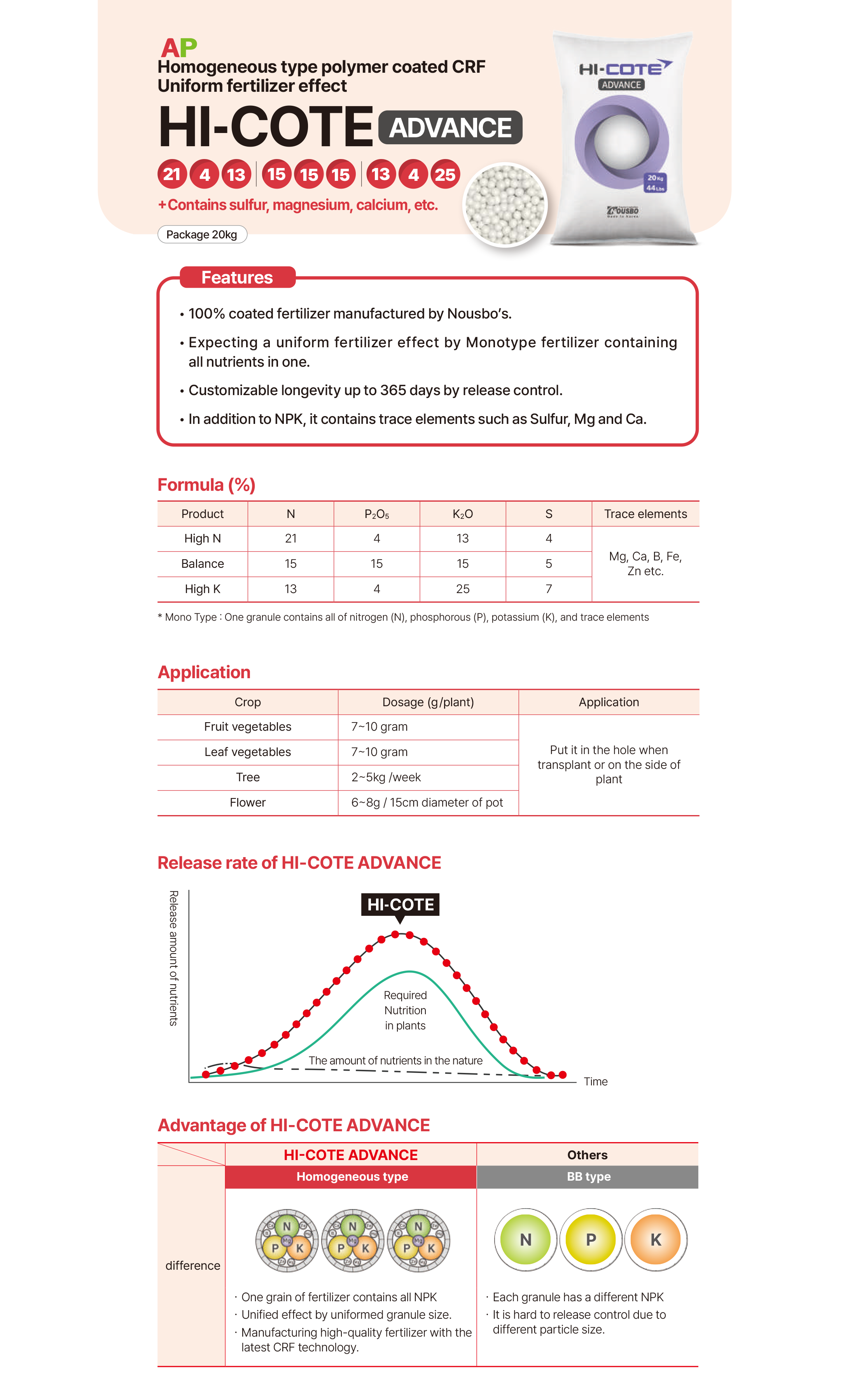

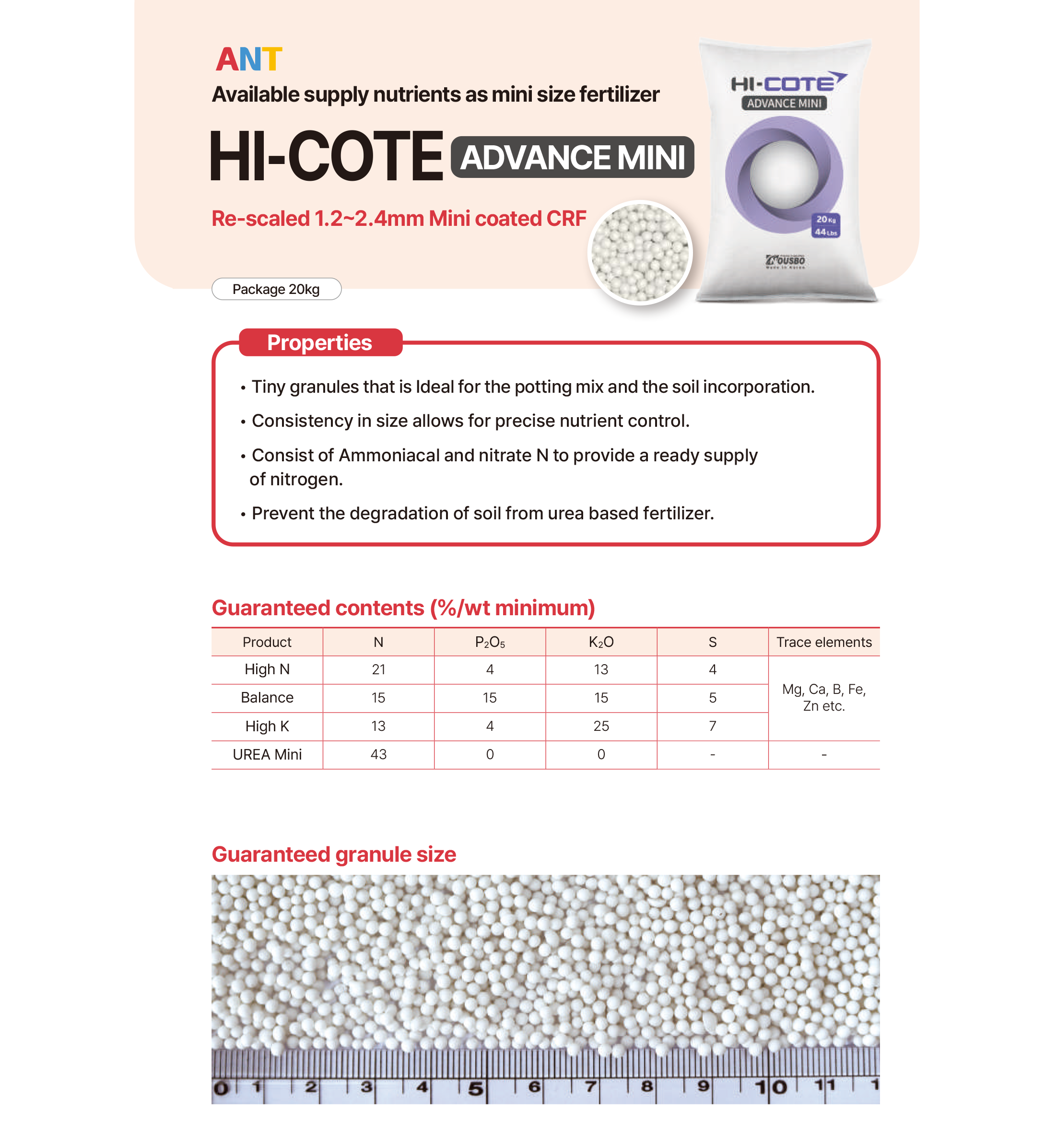

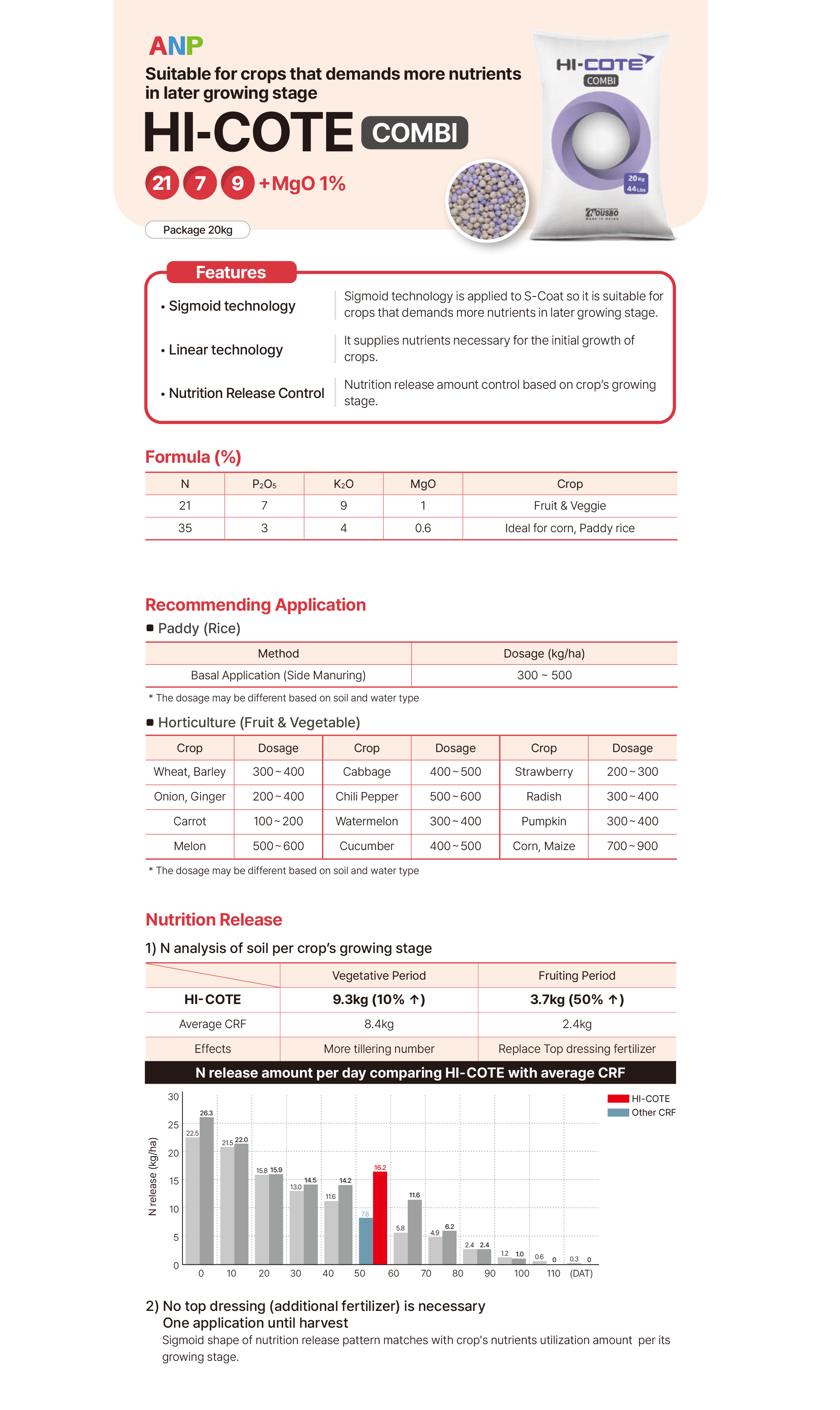

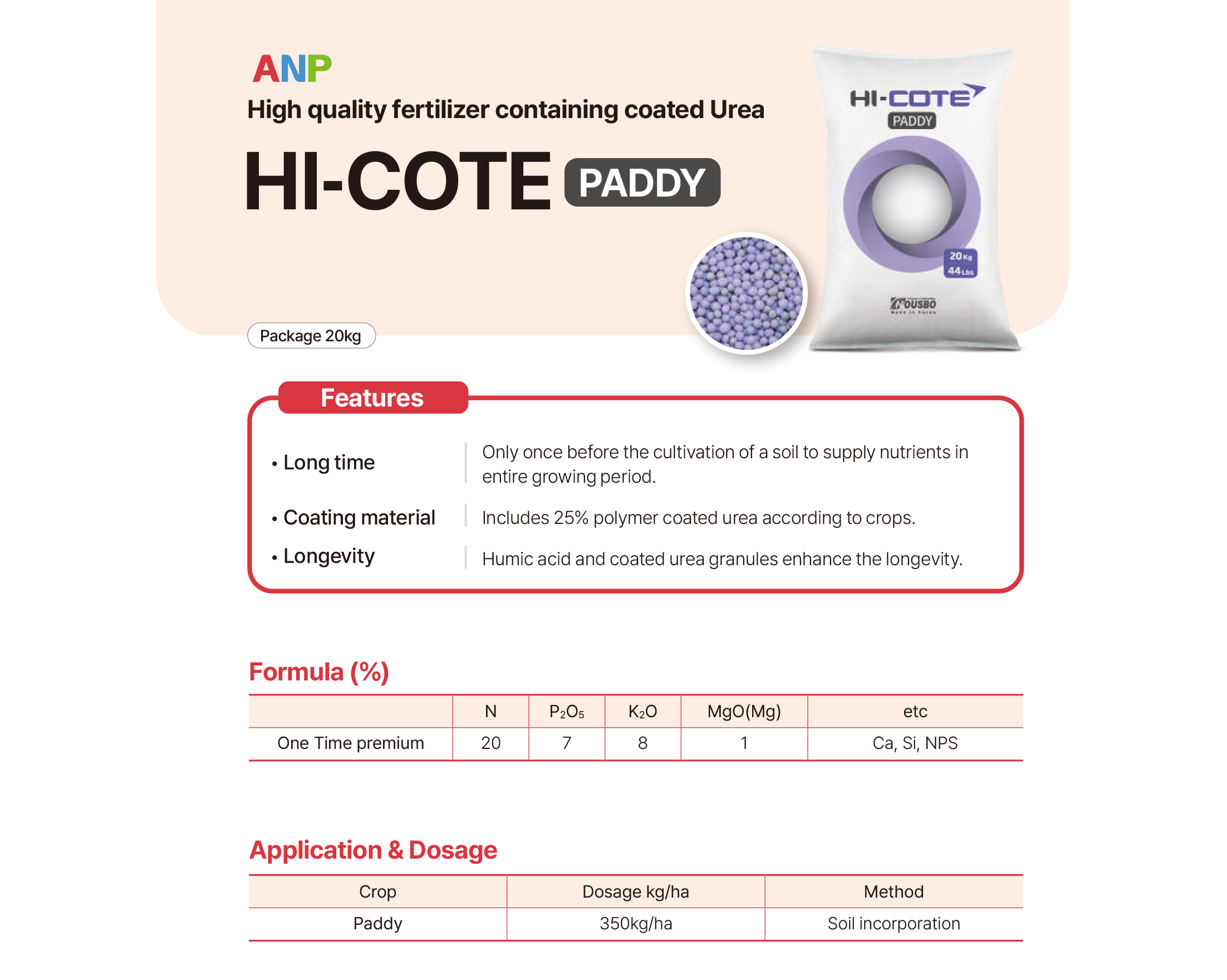

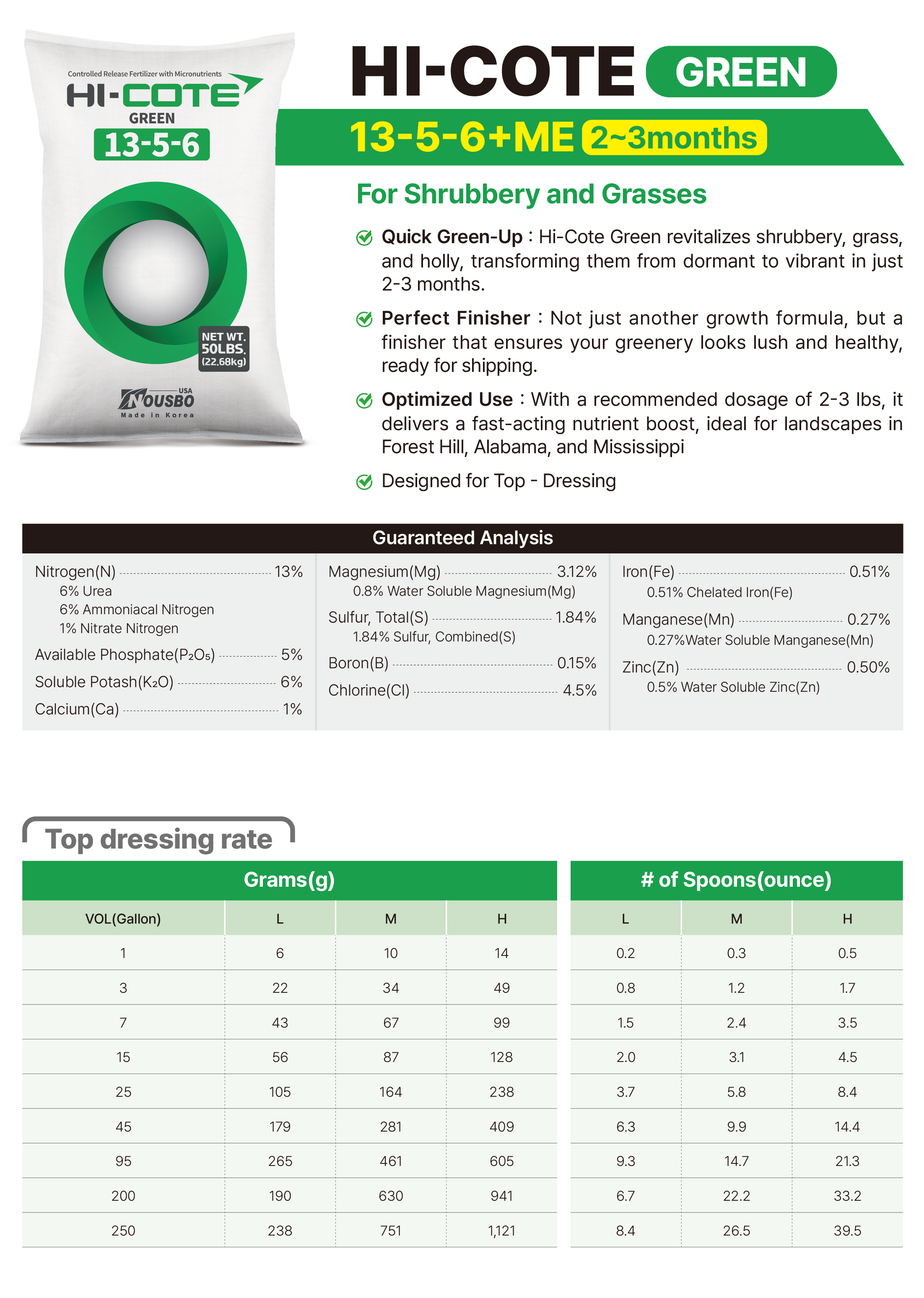

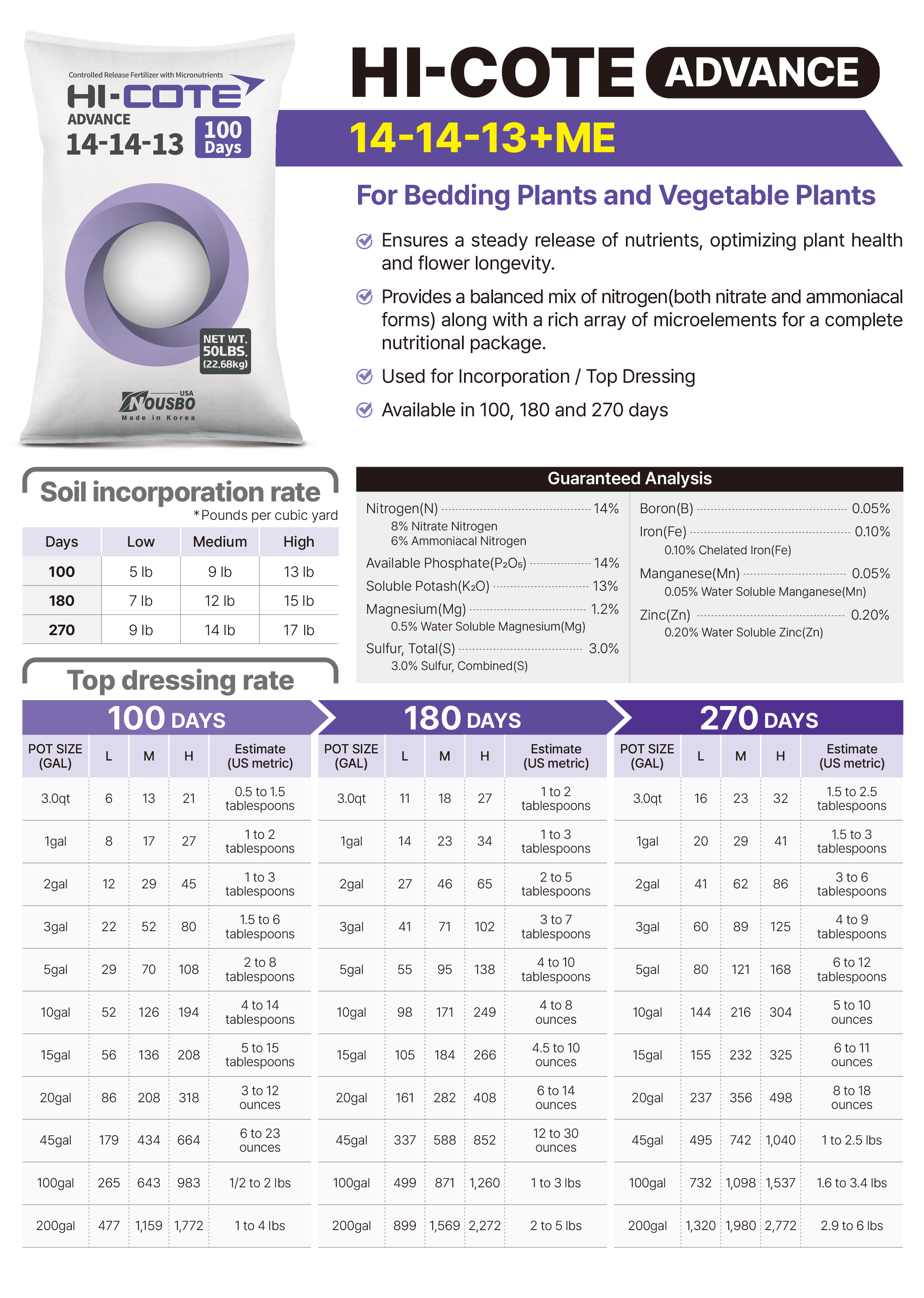

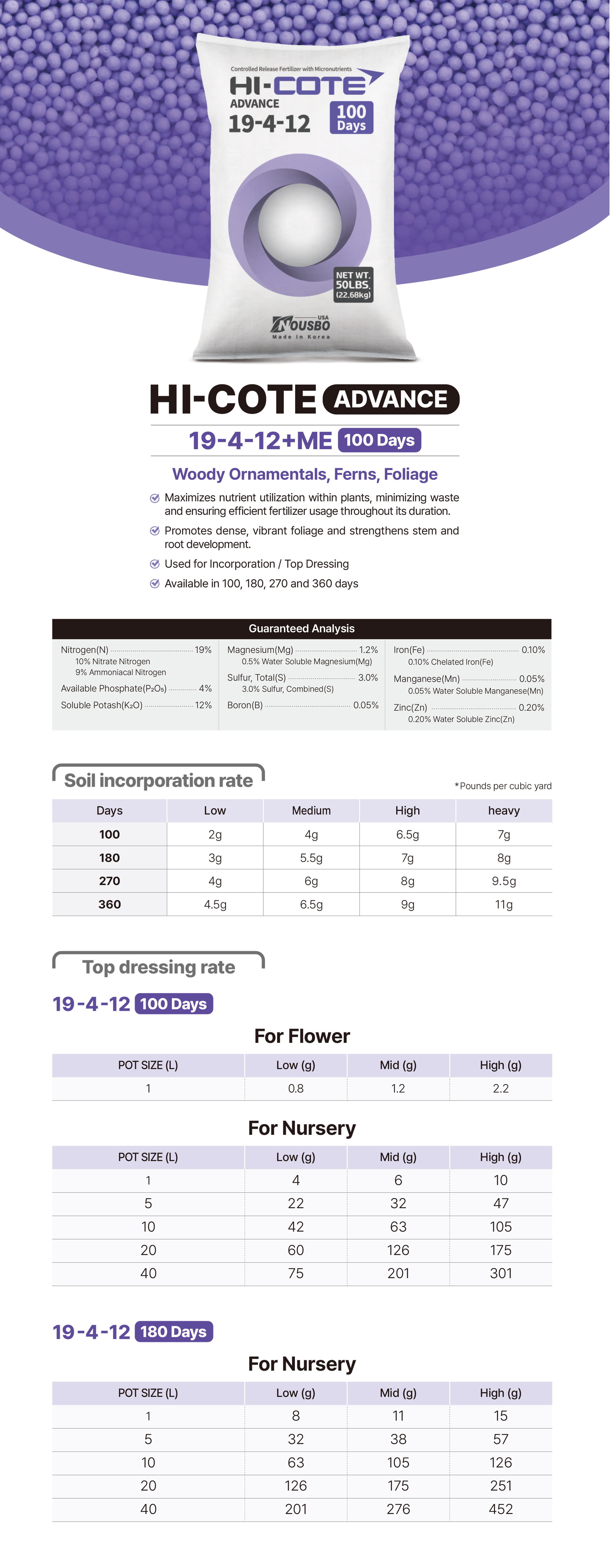

Hi-Cote is a specialized fertilizer covered with a material that facilitates the gradual release of nutrients, ensuring a continuous and optimal nutrient supply throughout the plant's growth period.

Hi-COTE Coating Process

The CRF Coating Process involves spraying of coating material onto a fertilizer granule, resulting in the formation of a coating capsule.

The uniformity and accuracy of Nousbo CRF are achieved through the application of a special coating technology.

02. Adhesion

03. Coated Particle

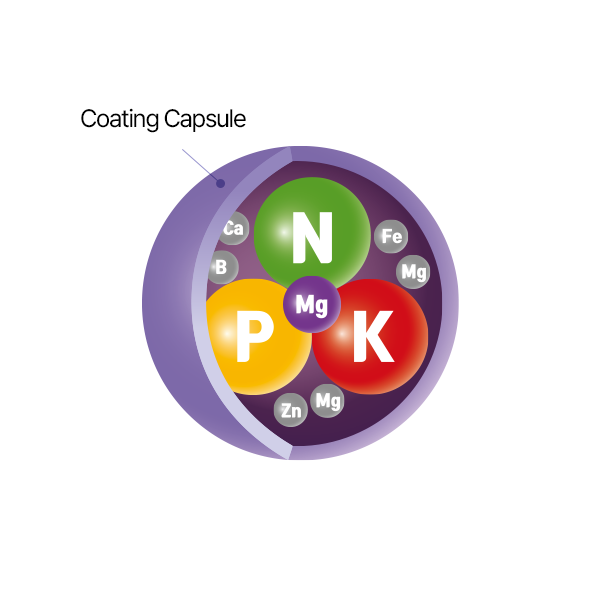

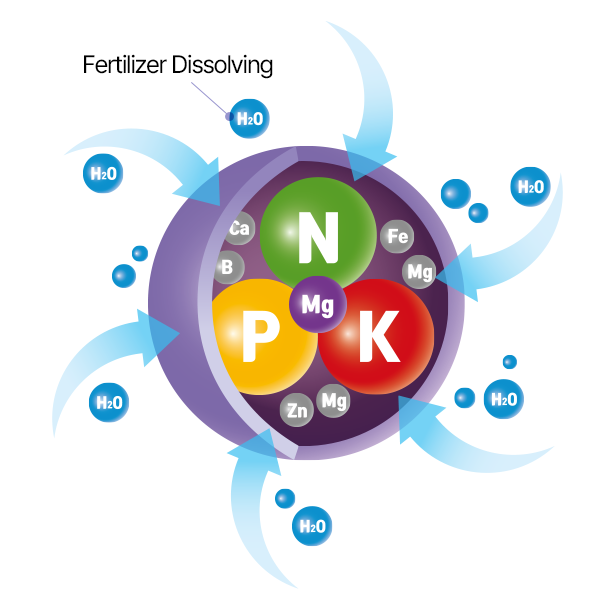

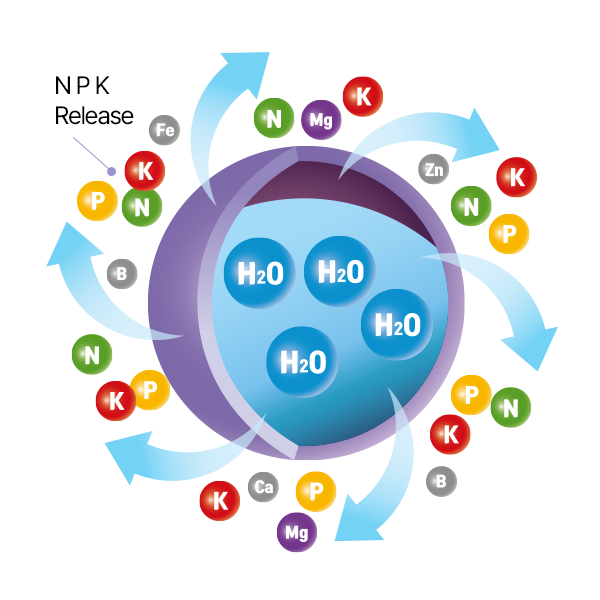

How does HI-COTE Work?

Nutrient release of Hi-COTE

Nutrient release of the CRF occurs in three steps: Moisture penetration into the capsule; Fertilizer Dissolution; Nutrients release by osmotic pressure. When granules are applied to the soil, water penetrates into the granules and dissolves nutrients, which are later gradually release into the soil.

Moisture Penetration

Fertilizer dissolving

Nutrients Release

Growth Pattern Alignment

Nutrients release after the temperature reaches seed sprouting levels and follow the corn growth pattern.

The coating material controls water penetration and availability of nutrients in forms preferred by plants, that result in maximizing crop yields.

Why use HI-COTE?

Quality control

-

- Precise and uniform coating technology

High Fertilizer Utilization and

Economical Efficiency

- Increases utilization by reducing fertilizer loss (leaching, volatilization, etc.)

- Reduces total fertilizer use

Labor Saving

- One time application provides all NPK requirements until harvesting

- Eliminates the need for additional top dressing

Eco-friendly

- Reduces groundwater pollution

- Reduces greenhouse gas emission

Media

We bring you various news about HI-COTE

Do you have any questions?

Nousbo values your opinions, and we are ready to listen through our customer inquiry page. Leave your inquiries, and we will respond to you with sincerity.

US Contact

P.O. Box 22472 Houston, TX 77227

Tel : +1(334)419-3700

E-mail : nousbousa@nousbo.com

Head Office

#5-106, 89 Seoho-ro, Gwonseon-gu, Suwon-si, Gyeonggi-do, Korea

Tel : +82-1544-3098

E-mail : nousbo@nousbo.com